By Cole Stanton

It’s vital that your team is equipped with the tools that allow you to walk away from a job well-done the first time.

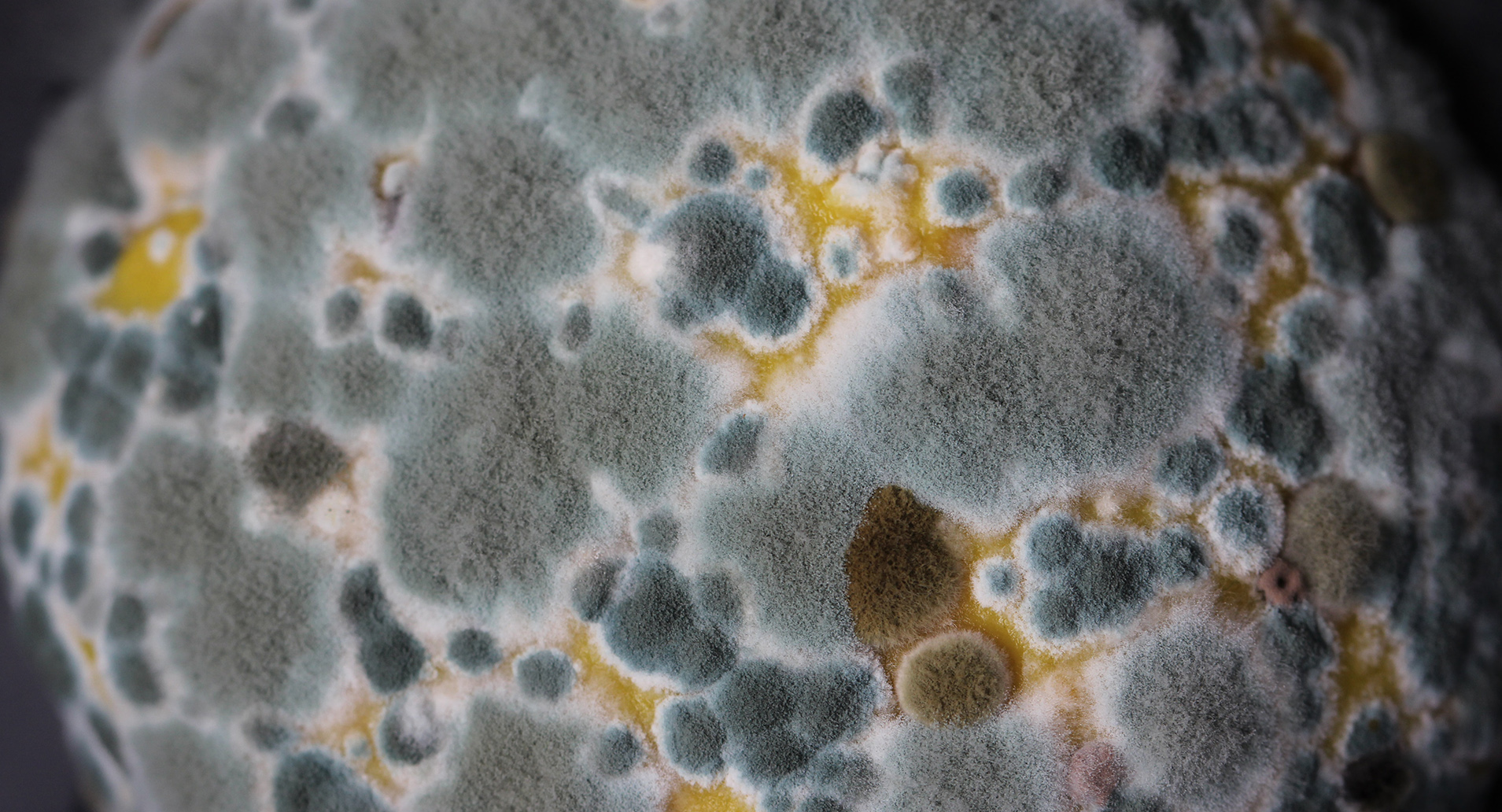

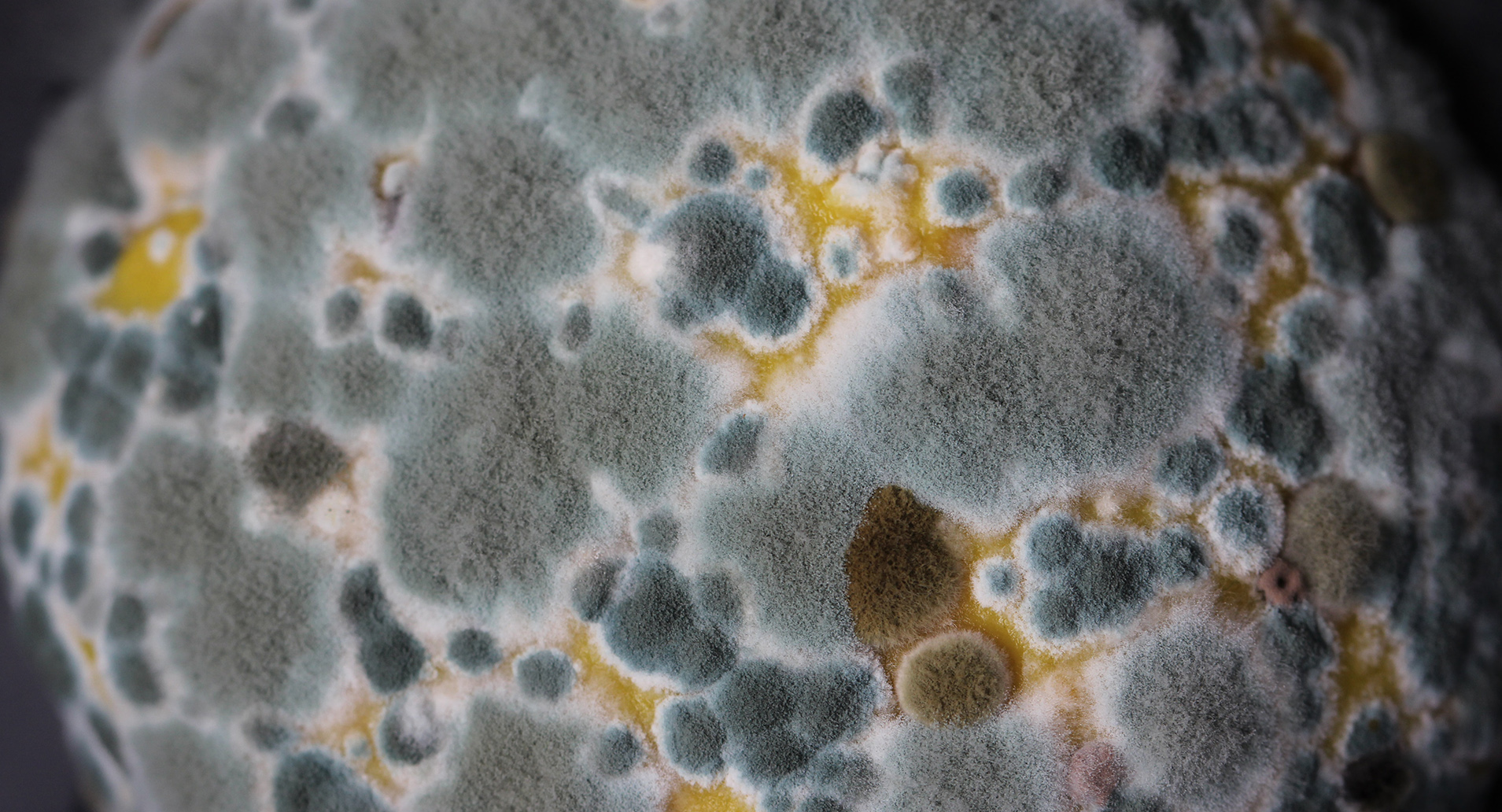

One of the most satisfying and fulfilling feelings for a mold and remediation professional is when a large-scale project comes together. On the flip side, however, one of the most discouraging events is when a finished project turns out to be not-so-finished. Not only is this frustrating for the team involved, but it is inefficient, costly, and can negatively affect a company’s reputation.

Therefore, it’s vital that your team is equipped with the tools that allow you to walk away from a job well-done the first time. One of those tools is a high-performance mold-resistant coating. Mold-resistant coatings do two jobs: First, they encapsulate any spores that may remain on a surface following a thorough cleaning and disinfecting, preventing them from becoming a problem later on; second, they create a surface that is inhospitable for new mold growth in the future. Investing in the right coating will help ensure that new buildings stay mold-free.

When choosing your coating there are plenty of factors to consider. In fact, there are so many options to choose from that some brands will go as far as to create a custom coating through a production company. This is a special process, and, while it may work for some, it isn’t typically the most cost-effective method.

It’s additionally important to understand the purpose and the placement of your coating before selecting one. One of the most telling factors is whether you have an indoor or outdoor environment that needs coating. Depending on location, the weather can also drastically affect what properties are required of the coating itself. Though the use of mold-preventative coatings isn’t unheard of outdoors, the most common applications will be indoor spaces. There are always exceptions to the rule, but because of the way mold and fungi thrive in dark, warm, slightly moist areas, the plentiful nooks and crannies that spores can find indoors are the most likely places in need of attention.

The right mold-resistant coating, however, creates a world of difference.

Upfront Cost vs. Lifetime Cost

Cost will always be a factor in making the right choice for a project. However, it’s common for professionals to make the mistake of looking at an initial price point and equating that to the total cost. An important consideration when sourcing your products as a remediation pro is the lifetime value of the products and tools that you’re using. Much like the way machinery depreciates over time, using inferior products can lead to problems down the line. While investing in the proper coating upfront might have a higher purchase price point, the longevity and sustainability you gain will far outweigh the upfront price.

Consider IAQ 6000 from ICP Building Solutions Group, a durable, flexible, and permeable vinyl-acrylic water-based coating. While the cost of the IAQ 6000 sits around 76 cents/square foot, and the most comparable competitors are only slightly lower at 67 cents/square foot, the IAQ 6000 requires just one coat of coverage—competitors require two. When factoring in the cost of a second coat, the closest competitor price comes to a total of $1.34/square foot in material vs. the 76 cents/square foot price that you get by going with the superior product.

Additionally, the specification and use of a higher-performance mold-resistant coating at the start of a project can help reduce the likelihood of mold regrowth and the customer callbacks that may result. Backtracking is never efficient and is rarely enjoyable. It is, however, costly. Re-doing the same work twice takes time, labor, energy, and of course materials. Not to mention, with mold, if handled improperly, the likelihood of spores returning is rather high. While there is never a guarantee that mold extraction is 100% successful, with the right coating the chances of mold return are significantly lower.

Investing in the right coating upfront will help you prevent future mold outbreaks, whether you’re working on remediation after mold extraction or building a structure from scratch.

The Environmental Factor

With good reason, the awareness of the environmental impact of various products has come into much sharper focus over the last decade or so. This extends far beyond the scope of remediation and mold prevention, and every industry has begun to take steps toward supporting the wellness of our planet. That’s why the IAQ 6000 was reformulated to be a vinyl-acrylic, water-based coating, which no longer requires the prop 65 warning.

This is a win-win for you and your team. Not only will it allow your brand to gain the reputation of being sustainable and environmentally focused—by supporting and using sustainable products—but the wellness of the planet isn’t the only health issue at stake. The well-being of your team, staff, and contractors are all vital to your ability to go into the field and get work done.

Coating Products and ASTM

Much like other industry-standard and testing organizations, ASTM publishes a wide variety of industry standards and regulations that apply to a spectrum of areas. The ASTM D3273 is the standard test for mold-growth prevention on the surface of an interior environment. Passing this test with the highest rates possible, IAQ 6000 is one of the strongest fungistatic and anti-mold coatings for professional-grade use that’s on the market.

Using products that have been third-party tested should help you rest assured that you and your team are sourcing the safest and highest-quality products that are available. Ultimately, saving you time, energy, and of course, money.

Wrapping Up

Mold is a part of life, and in some ecosystems it’s absolutely vital. However, our homes, businesses, and other personal spaces are absolutely not those ecosystems. Architects and remediation professionals alike have a need for mold-preventative solutions and with IAQ 6000’s new formula, a solution has arrived.

The IAQ 6000 coating is both fungistatic and mold-preventative, requiring only one coat to be effective. The new formula doesn’t require a prop 65 warning as it’s vinyl acrylic and water-based, making it a healthy choice for the environment and your body. It’s also an excellent coating for indoor spaces as it has an 80% photon reflection rate; generating a perfect environment for healthy plant life where you choose to put it, while keeping out the mold from behind your walls.

Finally, there’s the matter of the bottom line. As noted earlier, when compared to the closest competitors that require two coats for coverage, IAQ 6000 only needs one, making the cost comparison a grand slam at a total cost of 76 cents/square foot vs $1.34/square foot.

Environmentally sound, third-party tested, and cost-effective compared to competitors, IAQ 6000 is the right choice for professionals seeking a reliable mold solution.