Why go botanical?

Think pure. Think clean. Think healthy.

What does it mean to go botanical? By definition, botanical means a substance that is derived from a plant. So why go botanical with your disinfectants? Consider that authentically botanical solutions can displace millions of pounds of synthetic chemicals from entering our ecosystem and our bodies―the air we breathe, the water we drink and the foods we enjoy are all made safer by products that pose no harm to our health.

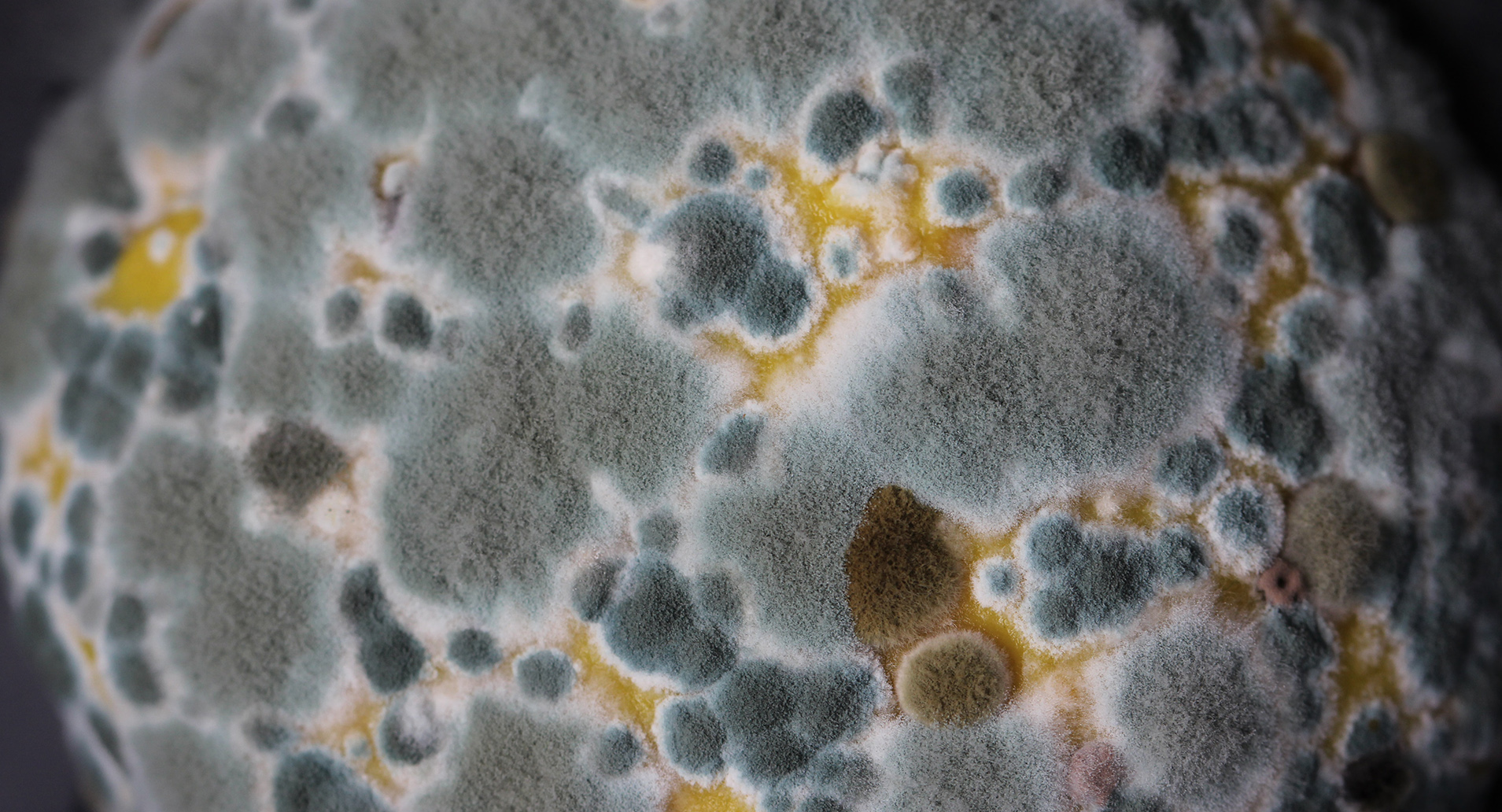

Standard Cleaning Products

Traditional cleaners and disinfectants may contain chemicals that produce VOCs (volatile organic compounds) that can be released into the environment through evaporation or introduced to water supplies via residual rinsing of mops, towels and sponges. VOCs are gases that can negatively affect indoor air quality and that contribute to outdoor air pollution.

Additionally, some active ingredients in synthetic disinfectants may biodegrade at a slow rate and pose a contamination risk if not properly treated. This can be harmful and even toxic to wildlife, especially aquatic animals, and can even make its way into our food chain. For example, alkylphenol ethoxylate, a common surfactant used in popular cleaners, has been shown in laboratory studies to function as an “endocrine disrupter,” causing adverse reproductive effects in wildlife exposed to polluted waters.*

Conventional cleaning products might also contain chemicals like nitrogen, phosphorus and ammonia that cannot be removed by waste treatment processes. Instead, these contaminants enter waterways and accumulate, triggering unnatural, accelerated growth for some plant life.

An authentically botanical disinfectant, however, uses only essential oils from nature to kill germs. There are no concerns about pollution nor product warning labels calling for layers of eye, skin and respiratory protection. By essentially bottling a plant’s immune system, the benefits add up when cleaning up anywhere.

The Botanical Solution

A truly botanical solution is a safer alternative to synthetic cleaners that may use bleach, phosphates, chlorine or other harsh chemicals. But that doesn’t mean bacteria and viruses have nothing to fear. Botanical products use ingredients taken from the earth, not produced in factories, to work just as hard as synthetic cleaners and disinfectants, but without harming people or the environment. In fact, many of the plant compounds contained in the world’s only authentically botanical disinfectant, Benefect®, are sourced directly from small family farms where the oils are extracted through an on-site distillation process.

We only formulate with safe, sustainable ingredients to create disinfectant products that use a proprietary blend of essential oils, including thyme, lemongrass and oregano, plus a biosurfactant―a cleaning and emulsifying component―derived from palm kernel, pharmaceutical-grade water and naturally occurring groundwater ions.

One distillation batch comes from just 2 acres of crops and is enough to produce 5,000 gallons of Benefect product that is pure but effective at killing germs―just like a plant’s immune system.

As a result, Benefect disinfectants and wipes are proven to kill 99.99% of bacteria and surpass the U.S. Environmental Protection Agency (EPA) efficacy requirements for a broad spectrum of uses. They also carry the highest safety rating allowable by the EPA, meaning less liability for cleaning professionals and facility managers.

In the same way our bodies produce antibodies to fight disease, plants produce germ-killing oils to protect from invading microbes. Benefect blends these antimicrobial extracts to give businesses more reasons to go botanical when disinfecting for better health and a healthier environment.

Is it pure?

Here’s what to watch for when selecting a botanical disinfectant solution:

Look for warning labels.

If a product says “warning,” “caution,” “harmful” or “danger,” it most likely is not botanical and contains harmful chemicals.

Read the description.

If the product label lists something you learned about in chemistry class or can’t pronounce, put it down. Botanical ingredients should contain known plants.

Don’t rely on marketing.

Many products are labeled “natural,” “organic” or “green,” but that does not mean they are safe. Check for third-party certifications on the label to verify information, like those from the U.S. Department of Agriculture, specifically of their BioPreferred® program. This program provides information about the true biobased contents of a product, which is measured by how much new organic carbon from pants is used compared to old organic carbon found in coal and petroleum.

Do your homework.

Know your products and the company. Learn what their philosophy is, how they make their products and from what ingredients.

Visit benefect.com to learn more and to read about why Benefect is the first and only 100% biobased disinfectant.

*Sourced by the United States Environmental Protection Agency